Keep Updated

- Home

- Eta 7750 chronograph movement overhaul

Eta 7750 chronograph movement overhaul

A complete watch overhaul of an ETA 7750 Chronograph movement

This article will give you a tour of servicing an ETA 7750 chronograph movement.

This movement is fitted on an IWC watch.

Specifications:

- Automatic one-direction.

- 28,800 vibrations per hour (4 HZ)

- 48-hour power reserve

- Hours, Minutes, Side second hand, Centre chronograph seconds, 30-minute counter, 12-hour counter, Day and Date.

- Swiss Made.

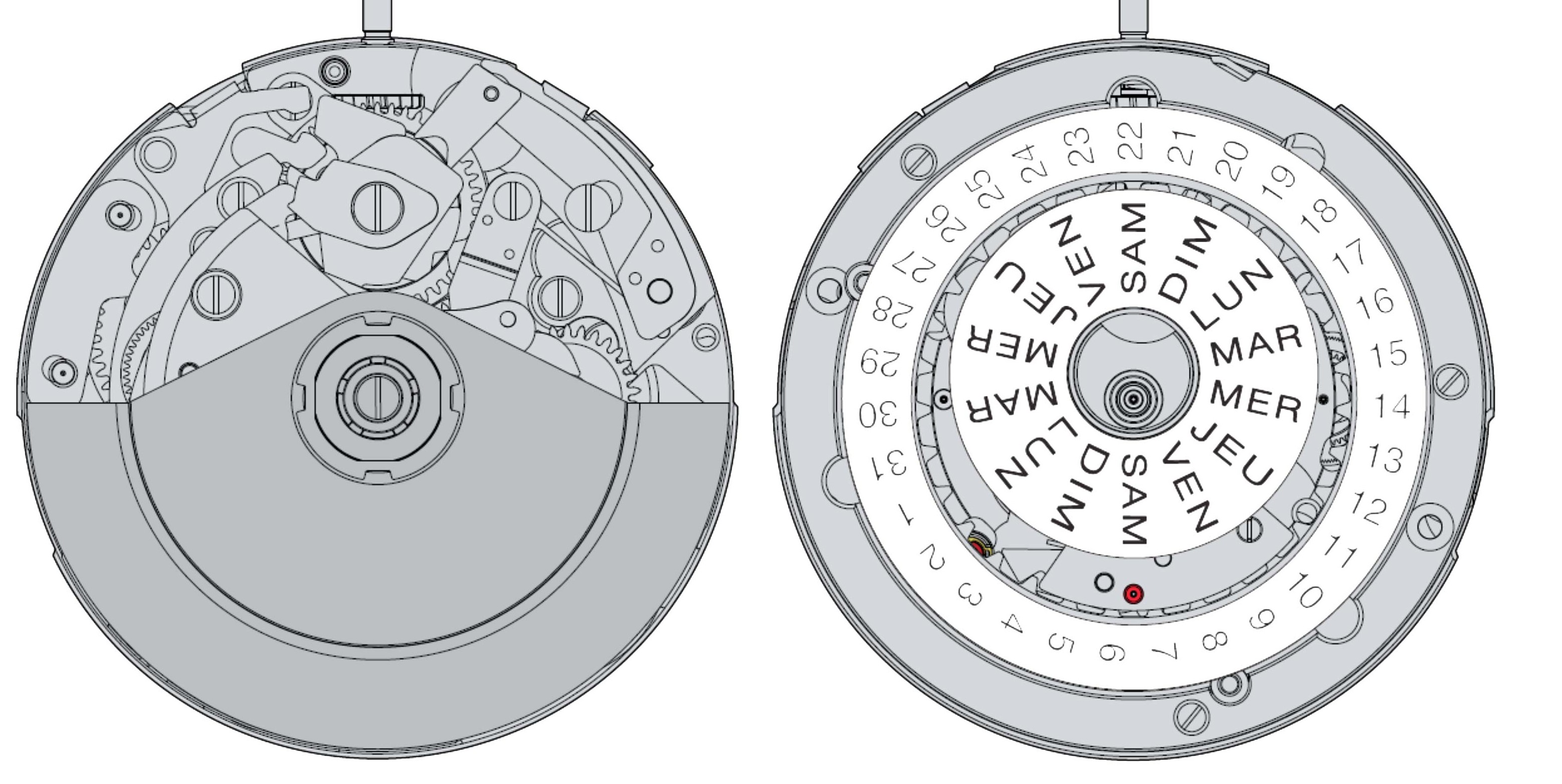

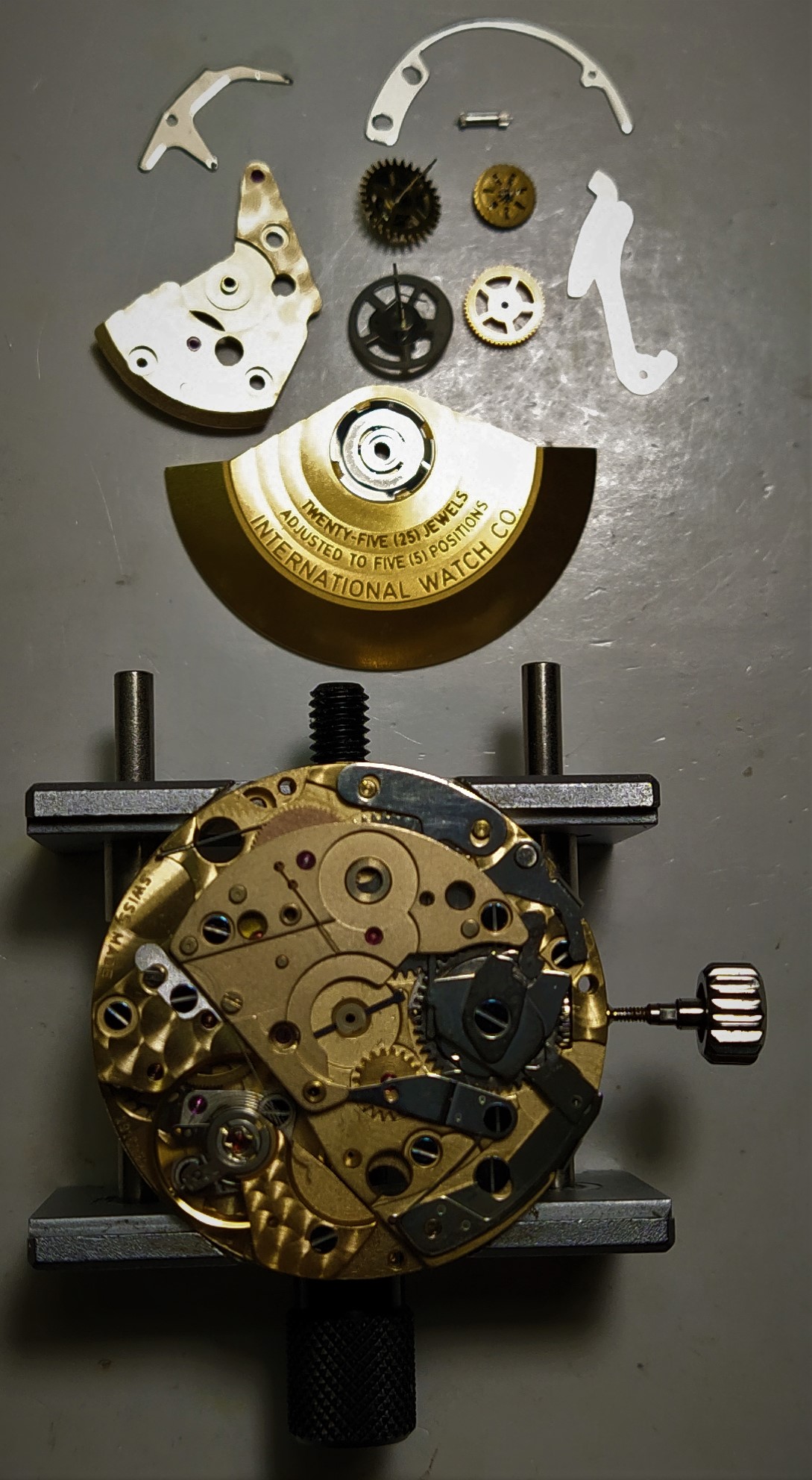

This is the complete movement removed from its stainless-steel case. Dial and hands were removed as well.

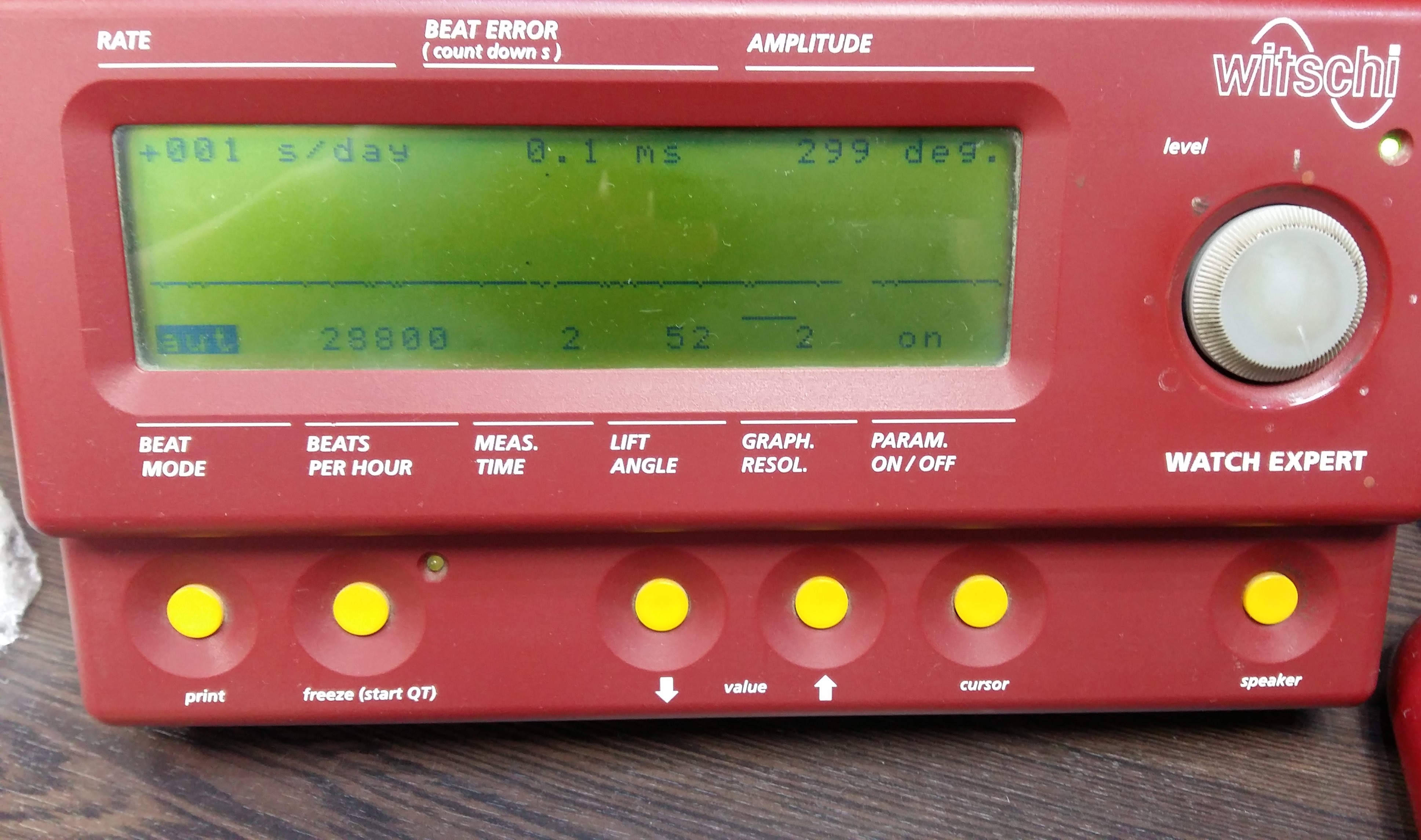

Prior to disassembling the movement, have been inspected and tested on a time graph machine. The diagnosis shows it needs servicing.

The movement will be completely disassembled, checked for wear and tear, cleaned, re-assembled, oiled and greased as per ETA instructions.

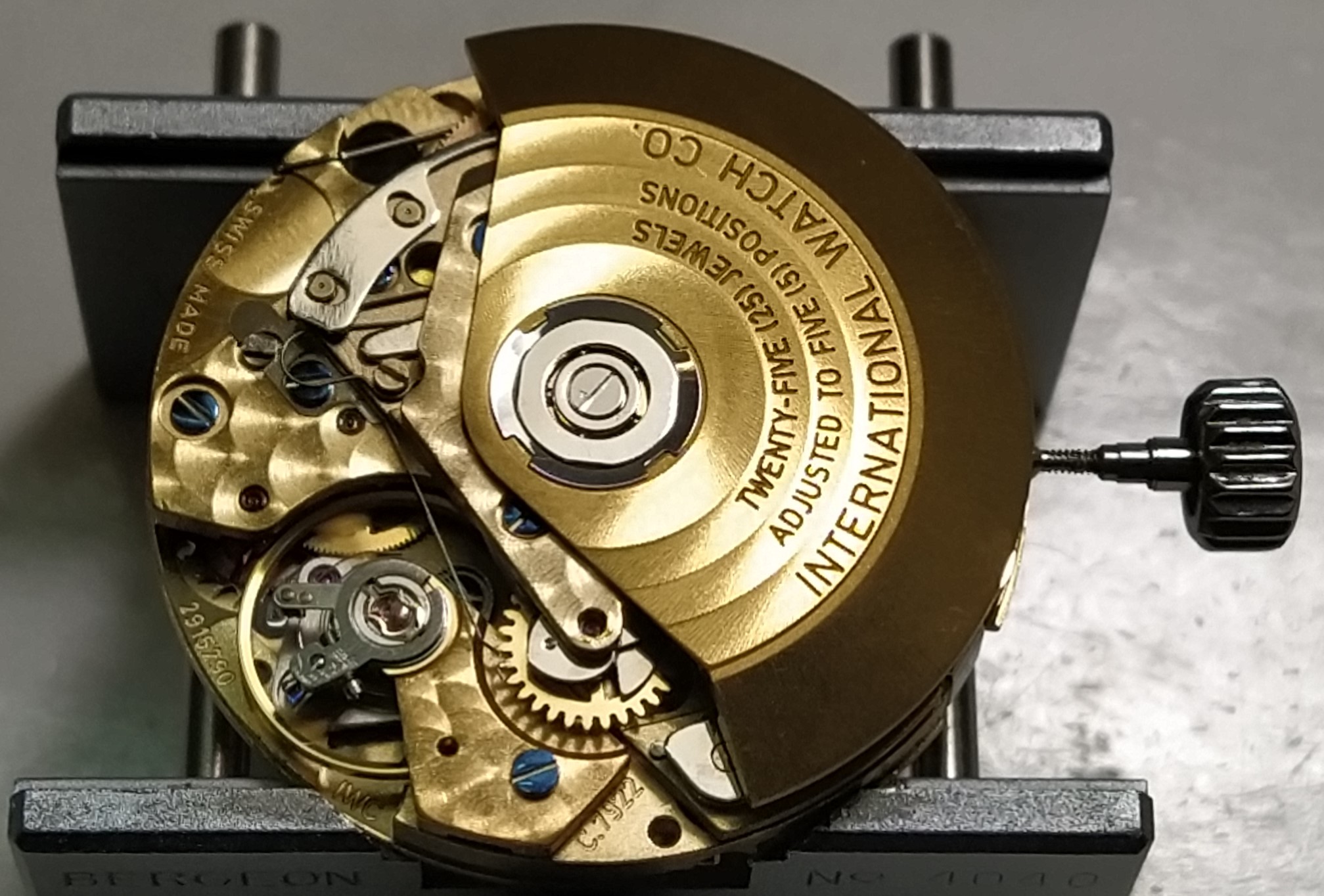

Removal of the automatic weight.

Here it reveals the top plate, which secures all the automatic and chronograph parts.

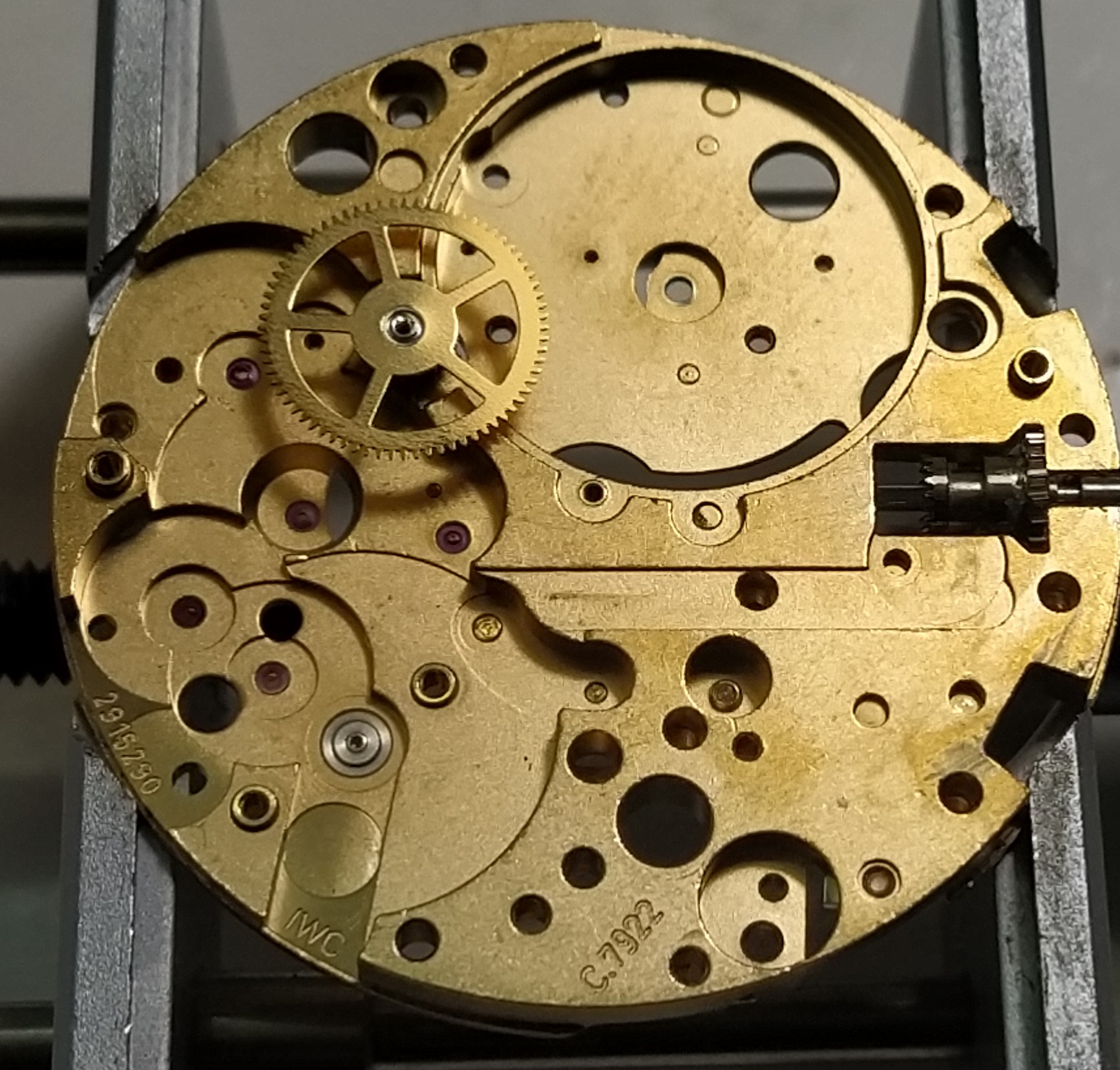

Automatic and most chronograph parts removed.

Complete disassembly of time train.

Complete disassembly of time train.

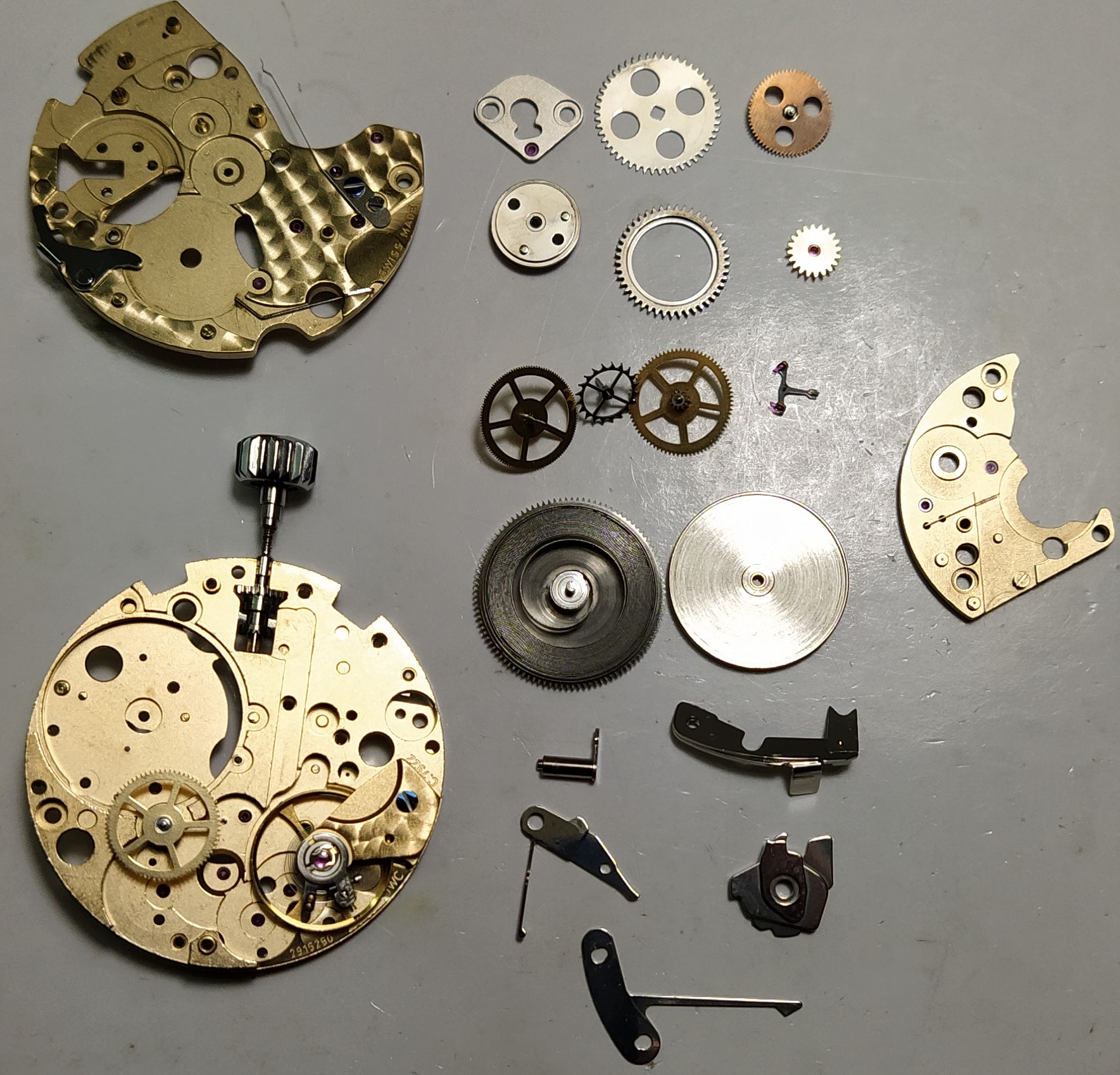

This is when all parts are checked for wear and tear before being placed in a special container ready for the cleaning machine.

All parts are ready for a 3-stage cleaning process, each time in different solutions to remove all old oil and grease completely.

A rinsing and drying process follows. All parts are re-checked before assembly.

First to be assembled is the time train.

This part of the mechanism holds the power source (a steel alloy main spring), the 4-time wheels, the pallet, and the balance wheel.

This is the basic part of the movement, the simplest section but the most important one since it assists all the other parts in following.

Next comes the chronograph centre seconds, the 30-minute counter, the automatic reversing wheel, the automatic weight and the chronograph reset function.

All other levers and springs assist the chronograph start and stop function.

That brings a full assembly of the back side of the movement.

This is the front side of the movement.

Here we can see all the time setting parts on the right-hand side of the movement. The day and date changing wheels, the 12 hour counter wheel and reset function, the minute and hour wheel.

Last to be assembled are the day and date parts, dial and hands.

A test on the time graph shows this movement is working beautifully with a timing of +1 second every 24 hours.

The movement is assembled back in its case which have been ultra sonic cleaned

The movement is assembled back in its case which have been ultra sonic cleaned

A 4-day test on a watch winder will give us the last results. Ensuring all functions are working well.

The last process is to let the watch run out of winding to make sure it runs for the full 48-hour power reserve.

Karol Demanuele.